Ama-Burrs ayinkinga evamile ekucutshungulweni kwensimbi, njengokubhola, ukuphenduka, ukugaya, nokusika insimbi yeshidi...

Enye yezingozi zama-burrs ukuthi kulula ukuwasika!Ukususa ama-burrs, umsebenzi wesibili obizwa ngokuthi i-deburring ngokuvamile uyadingeka.I-3 deburring kanye nokuqedwa konqenqema kwezingxenye ezinembayo kungabalelwa ku-30% wezindleko zengxenye eqediwe.Futhi, imisebenzi yokuqeda yesibili kunzima ukuzenzela, ngakho-ke ama-burrs aba yinkinga ekhohlisayo ngempela.

Indlela yokuxazululaI-BURRS

1 Ukukhipha imali mathupha

Lena indlela engokwesiko nevame ukusetshenziswa, kusetshenziswa amafayela (amafayela okwenziwa ngesandla namafayela womoya), i-sandpaper, ama-sander amabhande, amakhanda okugaya, njll. njengamathuluzi asizayo.

I-Disadvanamathegi: Izindleko zabasebenzi ziyabiza, ukusebenza kahle akuphakeme kakhulu, futhi kunzima ukususa izimbobo eziyinkimbinkimbi.

Izinto ezisetshenziswayo: Izidingo zobuchwepheshe zabasebenzi aziphezulu kakhulu, futhi ifanele i-aluminium alloy die castings enama-burrs amancane kanye nesakhiwo esilula somkhiqizo.

2 Ukufa ukukhokha

Ukuqothula kwenziwa ngokusebenzisa ukufa kokukhiqiza kanye ne-punch.

Ukungalungi: Kudinga inani elithile lokufa (i-rough die, fine die) izindleko zokukhiqiza, futhi kungase kudinge ukwenza i-shaping die.

Izinto ezisetshenziswayo: Ifanele i-aluminium alloy die castings enezindawo ezilula zokuhlukanisa, futhi ukusebenza kahle kanye nomphumela wokuqeda ungcono kunomsebenzi wezandla.

3 Ukugaya nokukhipha

Lolu hlobo lokususa luhlanganisa ukudlidliza, ukuqhunyiswa kwesihlabathi, ama-roller, njll., futhi okwamanje kusetshenziswa izitshalo ezisakazwa ngokufa.

Ukungalungi: Kunenkinga yokuthi ukususwa akuhlanzekile kakhulu, futhi ukucutshungulwa okulandelayo kwama-burrs asele noma ezinye izindlela zokususa kungadingeka.

Izinto ezisetshenziswayo: zilungele ama-castings amancane e-aluminium alloy namaqoqo amakhulu.

4 Ukukhishwa okuqandisiwe

Sebenzisa ukupholisa ukuze unciphise ngokushesha ama-burrs, bese ufafaza ama-projectile ukuze ususe ama-burrs.Intengo yezinto zokusebenza cishe i-200,000 noma i-300,000;

Izinto ezisebenzayo: Ifanele i-aluminium alloy die castings enogqinsi oluncane lwe-burr wall kanye nevolumu encane.

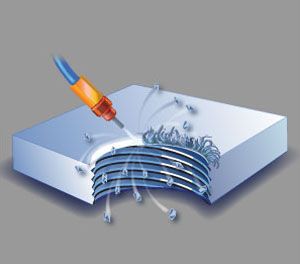

5 I-hot blast deburring

Okuphinde kubizwe nge-thermal deburring, i-explosion deburring.Ngokwethula igesi ethile evuthayo esithandweni sezinto zokusebenza, bese ngokwenza kweminye imidiya nezimo, igesi iqhuma ngaso leso sikhathi, futhi amandla akhiqizwe ukuqhuma asetshenziselwa ukuncibilikisa nokususa i-burr.

Ukungalungi: imishini ebizayo (izigidi zamaRandi), izidingo eziphakeme zobuchwepheshe zokusebenza, ukusebenza kahle okuphansi, imiphumela emibi (ukugqwala, ukuguqulwa);

Izinto ezisebenzayo: Ikakhulukazi esetshenziswa kwezinye izinkambu zezingxenye ezinemba okuphezulu, njengezingxenye zemoto kanye ne-aerospace.

6 Ukukhishwa komshini wokuqopha

Intengo yemishini ayibizi kakhulu (amashumi ezinkulungwane).

Izinto ezisetshenziswayo: Ifanele isakhiwo esilula sesikhala kanye nesikhundla esilula nesivamile sokususa.

7 Ukuchithwa kwamakhemikhali

Ngokusebenzisa isimiso sokusabela kwe-electrochemical, izingxenye ezenziwe ngezinto zensimbi zingakhishwa ngokuzenzakalelayo futhi ngokukhetha.

Izinto ezisebenzayo: ezifanele ama-burrs angaphakathi okunzima ukuwakhipha, afanele ama-burrs amancane (ubukhulu obungaphansi kwezintambo eziyisi-7) zemikhiqizo efana nemizimba yephampu nemizimba yamavalvu.

8 Ukukhishwa kwe-Electrolytic

Indlela yokwenza i-electrolytic yokukhipha ama-burrs e-aluminium alloy die-casting by electrolysis.I-Electrolytic deburring ifaneleka ukususa ama-burrs ezingxenyeni ezifihliwe ze-aluminium alloy die castings, izimbobo eziphambanayo noma izingxenye ezinobumo obuyinkimbinkimbi.Ukusebenza kahle kokukhiqiza kuphezulu, futhi isikhathi sokuvala ngokuvamile siyimizuzwana embalwa ukuya emashumini amasekhondi.

Ukubi: I-electrolyte igqwala ngezinga elithile, futhi indawo eseduze kwe-burr yezingxenye nayo ingaphansi kwe-electrolysis, indawo engaphezulu izolahlekelwa ukucwebezela kwayo kwasekuqaleni, futhi ithinte nokunemba kobukhulu.I-aluminium alloy die-casting kufanele ihlanzwe futhi ingagqwali ngemva kokubola.

Izinto ezisetshenziswayo: Ilungele ukudilizwa kwamagiya, izinduku zokuxhuma, imizimba yamavalvu nezimbobo zokudlula uwoyela we-crankshaft, kanye nokuzungezisa amakhona acijile.

9 I-high-pressure water jet deburring

Isebenzisa amanzi njengendlela ephakathi, ingasebenzisa amandla ayo okuthinta ngokushesha ukuze isuse ama-burrs kanye nokubaneka okukhiqizwa ngemva kokucubungula, futhi ngesikhathi esifanayo, ingafinyelela inhloso yokuhlanza.

Ububi: Imishini ebizayo

Izinto ezisetshenziswayo: ikakhulukazi ezisetshenziswa enhliziyweni yezimoto kanye nezinhlelo zokulawula ama-hydraulic emishini yokwakha.

10 Ukukhishwa kwe-Ultrasonic

Ukugaya okujwayelekile kokudlidliza kunzima ukubhekana nama-burrs afana nezimbobo.Inqubo evamile yokwenza imishini yokugeleza kwe-abrasive (ukugeleza kwezindlela ezimbili) iphusha okulimazayo kumasilinda abrasive amabili abheke phezulu ukuze alenze ligeleze liye emuva naphambili esiteshini esakhiwe ucezu lokusebenza kanye nendawo.Ukungena nokugeleza kwe-abrasive phakathi noma kunoma iyiphi indawo ekhawulelwe kuzoveza umphumela wokugwaza.Ingcindezi ye-extrusion ilawulwa ku-7-200bar (100-3000 psi), ifanele imivimbo ehlukene kanye nezikhathi zomjikelezo ohlukile.

Izinto ezisebenzayo: Ingakwazi ukuphatha ama-burrs amancane angu-0.35mm, awekho ama-burrs esibili akhiqizwayo, futhi izici zoketshezi zingakwazi ukuphatha ama-burrs ezindawo eziyinkimbinkimbi.

11 I-Abrasive flow deburring

Ukugaya okujwayelekile kokudlidliza kunzima ukubhekana nama-burrs afana nezimbobo.Inqubo evamile yokwenza imishini yokugeleza kwe-abrasive (ukugeleza kwezindlela ezimbili) iphusha okulimazayo kumasilinda abrasive amabili abheke phezulu ukuze alenze ligeleze liye emuva naphambili esiteshini esakhiwe ucezu lokusebenza kanye nendawo.Ukungena nokugeleza kwe-abrasive phakathi noma kunoma iyiphi indawo ekhawulelwe kuzoveza umphumela wokugwaza.Ingcindezi ye-extrusion ilawulwa ku-7-200bar (100-3000 psi), ifanele imivimbo ehlukene kanye nezikhathi zomjikelezo ohlukile.

Izinto ezisebenzayo: Ingakwazi ukuphatha ama-burrs amancane angu-0.35mm, awekho ama-burrs esibili akhiqizwayo, futhi izici zoketshezi zingakwazi ukuphatha ama-burrs ezindawo eziyinkimbinkimbi.

12 Ukukhishwa kwe-magnetic

Ukugaya kazibuthe ukuthi ngaphansi kwesenzo senkambu kazibuthe enamandla, ama-abrasive kazibuthe agcwaliswe endaweni kazibuthe ahlelwa ngendlela yemigqa kazibuthe, akhangiswe ezigxotsheni kazibuthe ukuze akhe "amabhulashi abrasive", futhi enze ingcindezi ethile kuwo. ubuso bomsebenzi, futhi izigxobo kazibuthe zishayela "ama-abrasives".Ngenkathi ibhulashi lijikeleza, ligcina igebe elithile futhi lihamba phezu kwendawo yokusebenza, ukuze libone ukuqedwa kobuso bomsebenzi.

Izici: izindleko eziphansi, ububanzi bokucubungula, ukusebenza okulula

Izingxenye zenqubo: i-grindstone, amandla kazibuthe, isivinini se-workpiece, njll.

13 Iyunithi yokugaya irobhothi

Umgomo ufana nokukhipha ama-manual, ngaphandle kokuthi amandla aguqulwa abe irobhothi.Ngokusekelwa ubuchwepheshe bokuhlela kanye nobuchwepheshe bokulawula amandla, ukugaya okuguquguqukayo (ukushintsha kwengcindezi nesivinini) kuyabonakala, futhi izinzuzo zokuchithwa kwerobhothi zivelele.

Uma eqhathaniswa nabantu, amarobhothi anezici: ukusebenza kahle okuthuthukisiwe, ikhwalithi ethuthukisiwe, nezindleko eziphakeme

Ama-Burrs Ezingxenyeni Ezigaywe Ezikhethekile

Ezingxenyeni ezigayiwe, ukuchithwa kuyinkimbinkimbi futhi kubiza kakhulu, njengoba ama-burrs amaningi akhiwa ezindaweni ezihlukene ezinosayizi abahlukene.Yilapho ukukhetha amapharamitha enqubo alungile ukuze unciphise usayizi we-burr kuba okubaluleke nakakhulu.

Isikhathi sokuthumela: Sep-29-2022